Corrugated vs. Cardboard: Understanding the Difference

The packaging world is vast and varied, offering a plethora of materials each suited to different needs and applications. Two terms often used interchangeably but incorrectly so, are “cardboard” and “corrugated.” While both materials are essential in the packaging industry, they serve distinct purposes and offer unique benefits. Understanding the differences between these materials is crucial for businesses and consumers alike to make informed decisions about packaging solutions that meet their needs effectively.

The Basics of Cardboard

Cardboard is a generic term that refers to a heavy-duty paper stock or thick paper pulp. This material can be found in a variety of everyday items, including cereal boxes, shoe boxes, and other types of packaging that require a stiff, but not necessarily strong, material. Cardboard is ideal for products that don’t require extensive protection during shipping or storage. Its primary advantage is its cost-effectiveness and ease of recycling, making it a popular choice for a wide range of applications.

The Strength of Corrugated

Corrugated, on the other hand, is a robust packaging material created by sandwiching a fluted, or wavy, layer of paper between two liners. This unique structure provides corrugated with significant strength and durability, making it the go-to choice for shipping and transporting goods that require additional protection. The corrugated material is designed to absorb impact, prevent damage, and can be customized in various ways to suit specific packaging needs.

Types of Corrugated

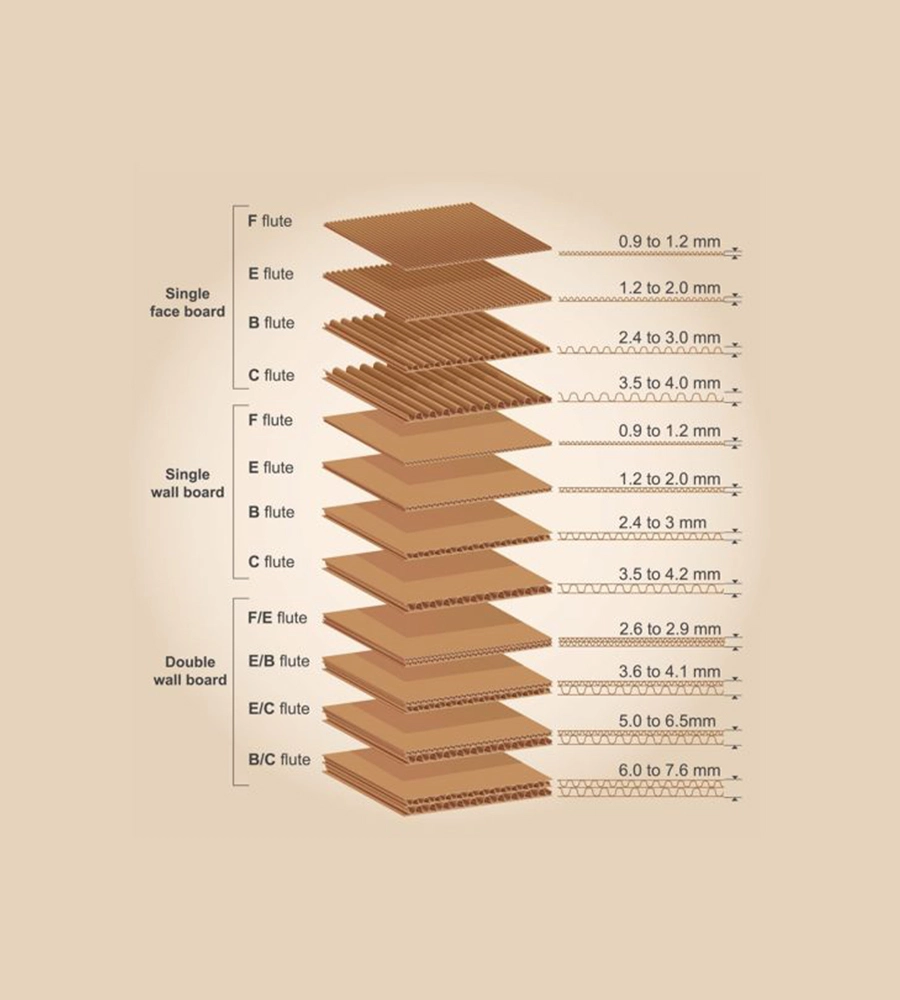

Understanding the different types of corrugated is essential for selecting the right packaging material for your product. The four main varieties of corrugated include:

- Single Face: This variety features a single sheet of fluted paper attached to one liner. It’s commonly used as a wrapping material or as padding to protect items inside a box.

- Single Wall: The most common type of corrugated material, single wall consists of a fluted sheet sandwiched between two liners. It offers a good balance of strength and flexibility, suitable for a wide range of packaging applications.

- Double Wall: As the name suggests, double wall corrugated combines a single face and single wall, resulting in two layers of flutes between three liners. This type offers enhanced durability and cushioning, making it ideal for heavier items or products that require extra protection.

- Triple Wall: The strongest of the corrugated options, triple wall corrugated joins two single faces with a single wall, featuring three layers of flutes between four liners. It’s designed for very heavy or fragile items, providing maximum protection and rigidity.

Choosing Between Cardboard and Corrugated

When deciding between cardboard and corrugated for packaging needs, consider the following factors:

- Product Weight and Fragility: Heavier and more fragile items will benefit from the superior protection offered by corrugated materials, especially double or triple wall options.

- Shipping and Handling: If your product will be subjected to long shipping distances or multiple handling points, corrugated’s shock-absorbing properties can minimize the risk of damage.

- Cost Considerations: While corrugated tends to be more expensive than cardboard due to its increased durability and protective qualities, it may ultimately save costs associated with damaged goods and returns.

- Environmental Impact: Both cardboard and corrugated materials can be recycled, but it’s important to consider the lifecycle of your packaging and choose materials that align with your environmental goals. Corrugated, with its ability to be reused and recycled multiple times, often represents a more sustainable choice.

Conclusion

In the debate between corrugated vs. cardboard, the right choice depends on the specific needs of your product and your business objectives. While cardboard offers an economical and practical solution for lighter, less fragile items, corrugated provides the necessary strength and protection for shipping and handling more substantial goods. By understanding the differences and applications of these materials, businesses can ensure their products are packaged in a way that is both cost-effective and secure, minimizing waste and maximizing customer satisfaction.

Share this:

Find the Ideal Packaging Solution

Our innovative, eco-friendly options ensure product safety, enhance efficiency, and reduce environmental impact. Tailored to meet your diverse needs, our packaging solutions promise durability, aesthetic appeal, and cost-effectiveness.

Explore Options